Ukuphuculwa okuqhubekayo kunye nokuveliswa kwe-aluminium yokunyibilika kunye neteknoloji yokuphosa

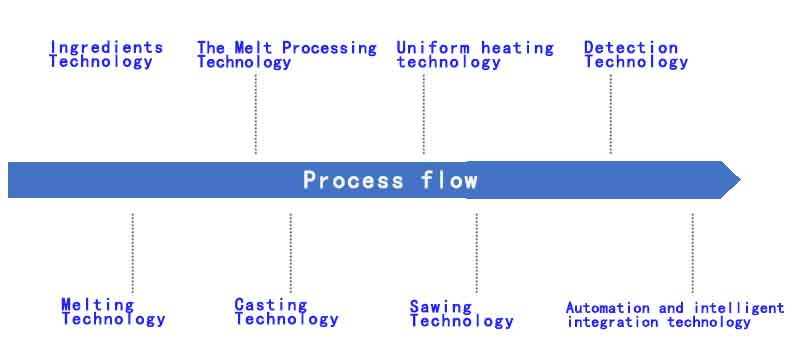

Ukunyibilika kwe-aluminiyam kunye neteknoloji yokuphosa ubukhulu becala ibhekisa kubuchwepheshe obahlukeneyo obubandakanyekayo kwinkqubo yokuvelisa iphepha, umcu, ifoyile kunye netyhubhu, intonga kunye nezikhewu zeprofayili.Ubuchwephesha obufana nokuntywila, ukusarha, ukuvavanya kunye nokuzenzekelayo kunye nokudibanisa okukrelekrele.Okwangoku, esona sixhobo sisisiseko sokucwangciswa kwe-workshop yokuphosa ibandakanya ukunyibilika nokubamba isithando somlilo (okanye i-aluminium yokunyibilikisa isithando somlilo kunye nesithando somlilo), ukuhlamba impahla, inkqubo yokucubungula i-intanethi, umatshini wokuphosa, njl.

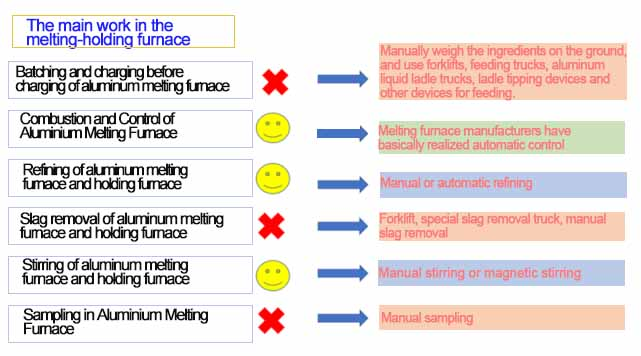

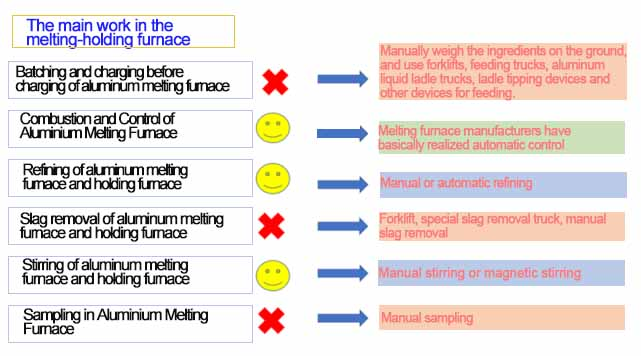

Ukususela kwimeko yokwenene yokuvelisa i-workshop yokuphosa, imisebenzi ephambili ibandakanya ukutya, ukususwa kwe-slag, ukutya, ukucocwa, ukulungiswa kwesikhunta, ukucoca, ukuphakamisa, ukuthutha, ukubeka, ukulayishwa kunye nokukhulula, ukubethelwa, ukulayishwa, njl. Ukongeza, kukho kwakhona Kukho ukutya okumanzi, ukutya okuqinileyo, ukucocwa kwecala lomlilo njalo njalo.Ekusebenzeni kwangempela, ukufumanisa ukuvuza kwe-aluminium yangoku kunye nokufaka iplagi kwinqanaba lokuphosa kusafuna umsebenzi wezandla, ofuna umsebenzi omkhulu kunye nomngcipheko ophezulu.Ukongeza, imisebenzi yezandla iyafuneka ukucoca kunye nokugcinwa kwesikhunta emva kokuphela.Ngokuthelekisa, ubuninzi bomsebenzi onjengokulawula ngokuzenzekelayo kunye neengots zokuxhoma ziye zasonjululwa.Emva kokuphosa kunye nokukhupha ii-ingots, ngokusebenzisa itafile yokugcina i-roller, umatshini wokusarha, isithando somlilo (kubandakanywa negumbi lokuhlamba, igumbi lokupholisa, imoto yokutya, njl. .), ii-detectors eziphosakeleyo, ukulinganisa, ukulinganisa, ukulayisha kunye nezinye iinkqubo zongezwa yinkqubo ye-MES ukudibanisa yonke inkqubo yokufezekisa imveliso ehlakaniphile kunye neqhubekayo.

Ke ngoko, okwangoku, kusekho iingxaki ezinjengokucwangciswa kwezixhobo ezingalinganiyo kunye nonxulumano olubi lolungiselelo phakathi kwemigca yemveliso.Nangona kunjalo, ngophuhliso lwetheknoloji, ukusetyenziswa okudibeneyo kunye nokulungelelaniswa kwezixhobo okwangoku zidibaniswa ngeenkqubo ezahlukeneyo zolawulo, kwaye ukusebenza kakuhle kwemveliso kuphuculwe.Iphuculwe, kwaye indibano yocweyo yokuphosa iphuhliselwe ukuya kubukrelekrele.

Ukusuka kwimeko yangoku yokusetyenziswa kwe-aluminiyam yokunyibilika kunye nokuphosa iteknoloji, ubugcisa obusetyenziswa ngoku ikakhulu bubandakanya iteknoloji yokunyibilika kokufudumeza, iteknoloji yokunyibilikisa, iteknoloji yokuphosa, kunye nobunye ubugcisa beworkshop.Itekhnoloji yokufudumeza exhaphakileyo esetyenziswa ngokuqhelekileyo kukutshisa okuhlaziyiweyo kunye nokutsha kwe-speed-speed burner kubushushu begesi, ngaphezu kokufudumeza kombane kunye nokufudumeza okujikelezayo.Itekhnoloji yonyango lwe-Melt ibandakanya unyango lwangaphambi kwesithando somlilo, unyango lweziko, ukuchithwa kwe-intanethi, ukususwa kwe-slag, ukulungiswa kweenkozo kunye nobunye ubuchwepheshe.Itekhnoloji yokuphosa ibandakanya i-ingot ecaba, i-ingot engqukuva, itekhnoloji yokuphosa kunye ne-rolling strip, kunye nobunye ubugcisa beworkshop bubandakanya itekhnoloji yokufunxa, itekhnoloji yokupholisa, itekhnoloji yokusarha njalo njalo.

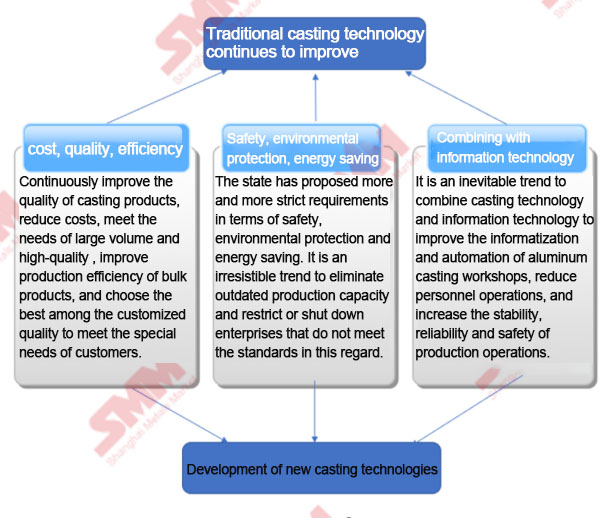

Okwangoku, uphuhliso lwangoku lwetekhnoloji yokuphosa ikakhulu ngenxa yokuhlalisana kwetekhnoloji yokuphosa, kwaye iimfuno zeemveliso ngokwexabiso, umgangatho kunye nokusebenza kakuhle ziphezulu kakhulu, ngelixa iimfuno zokhuseleko lokusingqongileyo, ukonga amandla kunye nokhuseleko. zomelezwa ngokuthe ngcembe.Njengoko ubugcisa obutsha buqhubeka buvela, iitekhnoloji eziphelelwe lixesha ngokuthe ngcembe zipheliswa.

Ngeemfuno zokhuphiswano kwishishini, ukulawulwa kunye nokukhokelwa kwemigaqo-nkqubo yesizwe, kunye nokuphuculwa okuqhubekayo kobugcisa bokuphosa, ayinikeli ingqwalasela engakumbi ekunciphiseni iindleko, ukuphucula umgangatho wemveliso, kunye nokuphucula ukusebenza kakuhle kwemveliso, kodwa ihlawula ingqalelo ngakumbi ukhuseleko lokusingqongileyo, ugcino lwamandla kunye neemfuno zokhuseleko.Indibaniselwano neteknoloji yolwazi ibe yinto engenakuphepheka.

Ukuncitshiswa kweendleko, ukongezwa ngokufanelekileyo, ukukhuselwa kwendalo kunye nokonga amandla zezona zikhokelo zophuhliso lwetekhnoloji entsha yokuphosa i-aluminium.

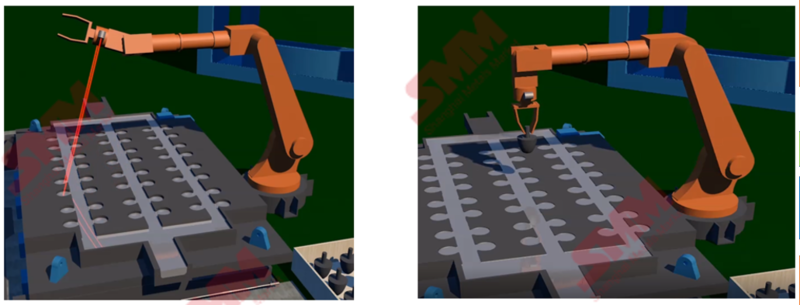

Phakathi kwetekhnoloji yokutya kunye nokususwa kwe-slag, kukho izithuthi ezizenzekelayo zokutya kunye nezithuthi ezizenzekelayo zokususa i-slag.Isetyenziselwa ukongeza izinto eziqinileyo, izinto ezingamanzi kunye ne-slag skimming phambi kwesithando somlilo.

Isixhobo sokususa i-alkali kwi-teknoloji yokucubungula i-melt isetyenziselwa ukulungiswa kwangaphambili kwe-electrolyte phambi kwesithando somlilo, kwaye iteknoloji yokucoca isithuthi isetyenziswe phambi kwesithando somlilo endaweni yokucoca ngesandla ukuphucula ukhuseleko.Isixhobo sokucoca i-oven side rotary degassing sisetyenziselwa ukusulungekiswa kwisithando somlilo, esingadingi ukungenelela komntu, siphucula ngokufanelekileyo ukusebenza kakuhle, kwaye siphucula nokhuseleko.Ukongeza, i-electromagnetic filtration

isixhobo sisetyenziswa ikakhulu kuhluzo lwe-intanethi, olunoncedo lokuchaneka okuphezulu kokucoca, ngokusisiseko akukho bumdaka obuziswayo, kunye nokuqhawula ngokulula kunye nokufakwa.Isixhobo se-ultrasonic degassing sinokuqonda ukuqaliswa kokungabikho kokungcola, izinga lokususa i-hydrogen liphezulu njenge-70%, kwaye iinkozo ziyakwazi ukucocwa ngelixa zicocwa.

Ngaphantsi kweemfuno ezisisiseko zokufumana ngokuqhubekayo umgangatho ophezulu we-aluminium alloy iyanyibilika kunye neebhilidi, iteknoloji yokunyibilika kunye nokuphosa idinga ukuqhubela phambili ukuhlangabezana neemfuno zemveliso yobuninzi bemveliso kunye nomgangatho wemveliso owenziwe ngokwezifiso.Ukuthandwa kwe-automation workshop kunye nemveliso ehlakaniphile kunokuphucula kakhulu ukusebenza kwemveliso kunye nokuhlangabezana neemfuno zeemveliso ezininzi.Kwangaxeshanye, ukukhawulezisa ukukhuthaza itekhnoloji yokuhlanjululwa kwenyibilika yamva nje kunye netekhnoloji yokuphosa kunokuphucula ngokufanelekileyo iimfuno zomgangatho weemveliso ezenziwe ngokwezifiso, kwaye ekugqibeleni zongezwa bubulumko kunye ne-automation.Itekhnoloji edityanisiweyo iphucula ngokupheleleyo uzinzo, ukhuseleko kunye nokuthembeka kwemveliso yeworkshop, kwaye iqinisekisa ubume obuphambili beworkshop malunga nokhuseleko lokusingqongileyo kunye nokonga amandla.

Ixesha lokuposa: Aug-15-2022