I. ukucutha

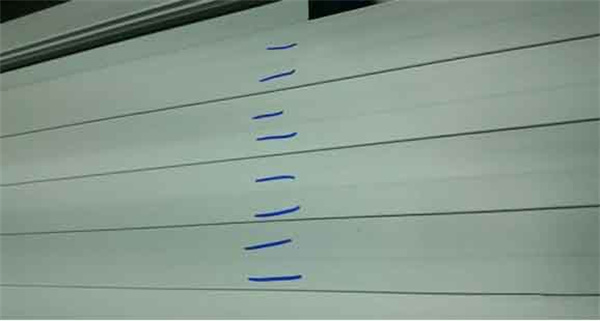

Ekupheleni komsila wezinye iimveliso ezikhutshiweyo, emva kokuhlolwa okuphantsi kokukhulisa, kukho into efana nophondo oluphakathi kwecandelo lomnqamlezo, elibizwa ngokuba ngumsila onciphayo.

Ngokuqhelekileyo, umsila wemveliso ye-extrusion yangaphambili ide kune-extrusion ye-reverse, kwaye i-alloy ethambileyo ide kune-alloy enzima.I-shrinkage yemveliso ekhutshiweyo ngaphambili ininzi ikwimo ye-annular disjoint layer, kwaye i-shrinkage ye-reverse extruded product is most in shape of the central funnel.

Isinyithi sigqithiselwa ngasemva, kunye nesikhumba se-ingot kunye nokufakwa kwamanye amazwe aqokelelwe kwikona efileyo ye-cylinder extrusion okanye i-gasket igeleza kwimveliso ukwenza i-shrinkage yesibini;xa izinto ezishiyekileyo zimfutshane kakhulu kwaye iziko lemveliso lingondliwa ngokwaneleyo, ifom luhlobo lwesifinyezo.Ukususela ekupheleni komsila ukuya phambili, umsila uya ulula kwaye unyamalale ngokupheleleyo.

Oyena nobangela wokucutheka

1. Izinto ezishiyekileyo zifutshane kakhulu okanye ubude bokuphela kwemveliso abuhambisani nemimiselo;

2. I-pad extrusion ayihlambulukanga kwaye ineoli yeoli;

3. Kwinqanaba lokugqibela le-extrusion, isantya se-extrusion sikhawuleza kakhulu okanye ngokukhawuleza sinyuka;

4. Sebenzisa iphedi yokukhama ekhubazekileyo (iphedi ephakanyisiweyo phakathi);

5. Iqondo lokushisa le-cylinder ye-extrusion liphezulu kakhulu;

6. I-cylinder ye-extrusion kunye ne-extrusion shaft ayihambelani;

7. Umphezulu we-ingot awuhlambulukanga, kukho ioli yeoli, i-tumor yokwahlula kunye nokugoqa kunye nezinye iziphene azisuswanga;

8. Umkhono wangaphakathi we-cylinder we-extrusion awuhlambulukanga okanye uphazamisekile, kwaye umgca wangaphakathi awucocwanga ngexesha lokucoca.

Indlela yokuthintela

1. Shiya intsalela kwaye usike imisila njengoko kufuneka;

2. Gcina umngundo ucocekile;

3. Ukuphucula umgangatho we-ingot;

4. Ukulawula ngokufanelekileyo ubushushu be-extrusion kunye nesantya sokuqinisekisa i-extrusion egudileyo;

5. Ngaphandle kweemeko ezikhethekileyo, kunqatshelwe ngokungqongqo ukusebenzisa ioli phezu kwesixhobo kunye nesikhunta;

6. I-gasket ipholile ngokufanelekileyo.

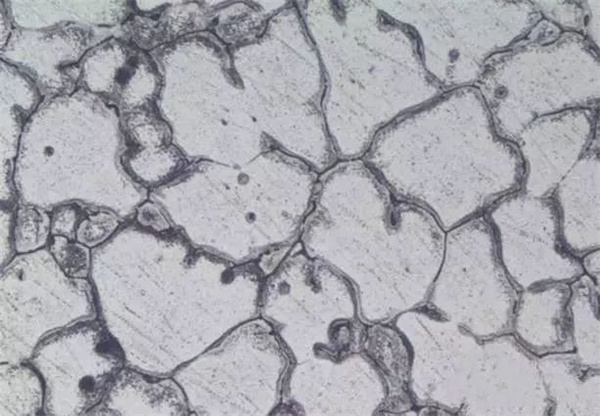

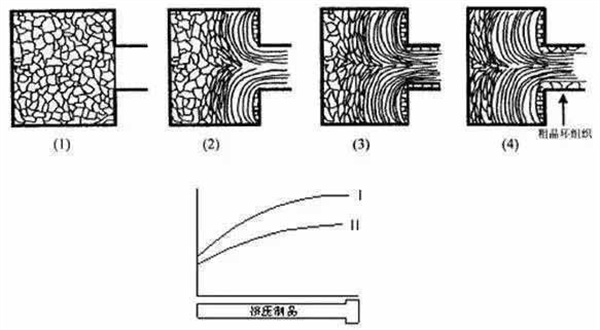

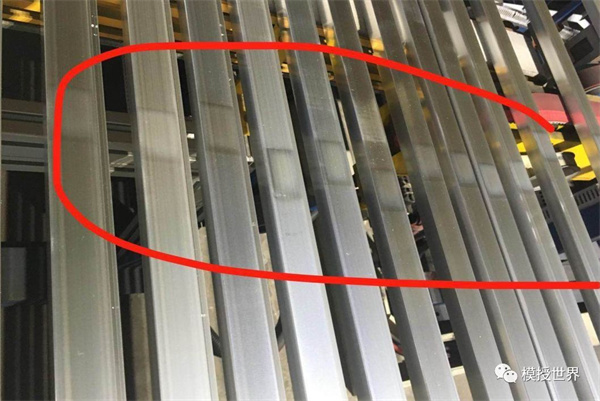

II.Iringi yekristale erhabaxa

Ezinye iimveliso ze-aluminiyam ezikhutshiweyo zenza indawo erhabaxa ephinde yahluzwa kwakhona yesakhiwo senkozo ecaleni komda wemveliso kwisiqwenga sovavanyo lokukhulisa okuphantsi emva konyango lwesisombululo, esibizwa ngokuba yiringi erhabaxa.Ngenxa yeemilo ezahlukeneyo kunye neendlela zokucubungula iimveliso, i-ring-shaped, i-arc-shaped kunye nezinye iifom ze-coarse-grained rings zingenziwa.Ubunzulu be-ring-grained coarse-grained buyancipha ngokuthe ngcembe ukusuka emsileni ukuya ngaphambili kwaye bunyamalale ngokupheleleyo.Indlela yokwakheka ephambili ngummandla we-sub-grain owenziwe kumphezulu wemveliso emva kwe-extrusion eshushu, kwaye ummandla wengqolowa owenziwe ngokutsha wenziwa emva kokufudumeza kunye nonyango lwesisombululo.

Oyena nobangela weringi yekristale erhabaxa

1. I-extrusion deformation engalinganiyo

2. Iqondo lokushisa lokushisa liphezulu kakhulu kwaye ixesha lokubamba lide kakhulu, ukwenzela ukuba iinkozo zikhule;

3. Ukwakhiwa kweekhemikhali zegolide akunangqiqo;

4. I-alloys ezomelezayo eziphathwa ngokushisa ngokubanzi zineendandatho ezinqabileyo emva kokunyanga ukushisa, ngokukodwa iimilo kunye nemivalo ye-6a02, i-2a50 kunye nezinye i-alloys zezona zinzima kakhulu, ezingenako ukupheliswa kwaye ziyakwazi ukulawulwa kuphela kuluhlu oluthile;

5. I-extrusion deformation incinci okanye i-deformation ayikwanelanga, okanye kwi-deformation range ebaluleke kakhulu, kwaye kulula ukuvelisa i-crystal ring coarse.

Indlela yokuthintela

1. Udonga lwangaphakathi lwe-cylinder ye-extrusion luhamba kakuhle kwaye lucocekile, lwenza umkhono opheleleyo we-aluminium ukunciphisa ukuxhatshazwa ngexesha lokukhupha;

2. I-deformation kufuneka ibe yinto epheleleyo kwaye ifane ngokusemandleni, kwaye iiparitha zenkqubo ezifana neqondo lokushisa kunye nesantya kufuneka zilawulwe ngokufanelekileyo;

3. Gwema isisombululo sokushisa kwesisombululo siphezulu kakhulu okanye ixesha lokubamba lide kakhulu;

4. Ukukhutshwa nge-porous die;

5. I-Extrusion nge-reverse extrusion method kunye ne-static extrusion method;

6. Iveliswe ngesisombululo unyango-umzobo-oguga indlela;

7. Lungisa ukwakheka kwegolide iyonke kwaye ukwandise i-recrystallization inhibitory element;

8. Sebenzisa i-extrusion ephezulu yokushisa;

9. Ezinye ii-ingots ze-alloy azikho homogenized, kwaye i-ring coarse grain ayinzulu ngexesha le-extrusion.

III, umaleko

Esi sisiphako se-delamination sesikhumba esakhiwe xa ukuhamba kwesinyithi kufana ngokufanayo, kwaye umphezulu we-ingot ugeleza kwimveliso kunye nojongano phakathi kokungunda kunye nesiphelo se-elastic zone yangaphambili.Kwisiqwenga sovavanyo sokwandisa okuphantsi, kubonakala ngathi kukho isiphene semigangatho eyahlukeneyo kumda wecandelo elinqamlezayo.

Oyena nobangela westratification

1. Kukho uthuli phezu kwe-ingot okanye i-ingot ine-aggregates enkulu yokwahlula endaweni yesikhumba semoto, izicubu zetsimbi, njl., ekulula ukwenza iileyile;

2. Kukho i-burrs phezu kwendawo engenanto okanye ukungcola okufana neoli yeoli, i-sawdust, njl., engacocwanga phambi kokukhutshwa;

3. Isikhundla somngxuma wokufa singenangqiqo, kufuphi nomda we-cylinder extrusion;

4. Isixhobo se-extrusion sigugile kakhulu okanye kukho ukungcola kwi-bushing ye-cylinder ye-extrusion, engenakucocwa kwaye ithathelwe indawo ngexesha;

5. Umahluko wedayamitha ye-pad extrusion inkulu kakhulu;

6. Iqondo lokushisa le-cylinder ye-extrusion liphezulu kakhulu kunelo ingot.

Indlela yokuthintela

1. Uyilo olufanelekileyo lokubumba, ukuhlolwa kwangexesha kunye nokutshintshwa kwezixhobo ezingafanelekanga;

2. Iingots ezingafanelekanga azifakwanga kwisithando somlilo;

3. Emva kokusika izinto eziseleyo, kufuneka zihlambuluke ngaphandle kokunamathela kwioli yokuthambisa;

4. Gcina umgca we-cylinder we-extrusion ucocekile, okanye ucoce i-lining ngexesha kunye ne-gasket.

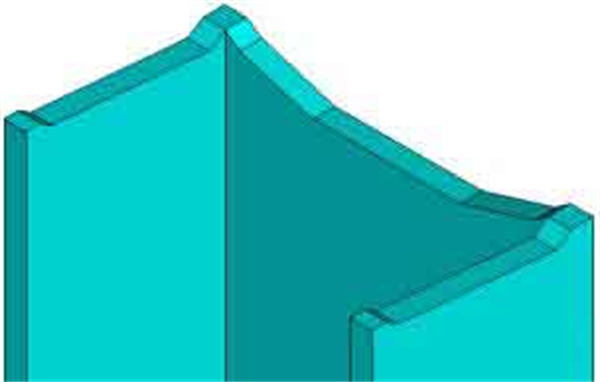

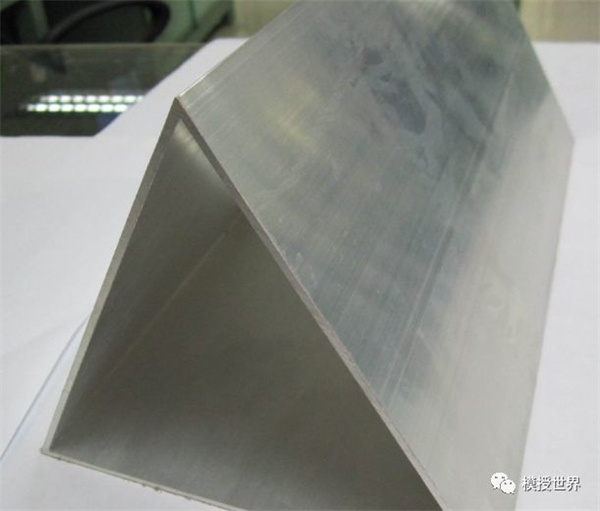

IV.Ukuwelda kakubi

Isenzeko se-weld delamination okanye i-welding engaphelelanga yemveliso engenanto ekhutshwe ngokuhlukana kwe-weld kwi-weld ibizwa ngokuba yi-welding engafanelekanga.

Oyena nobangela we-welding engalunganga

1. I-coefficient ye-extrusion incinci, i-extrusion ye-extrusion iphantsi, kwaye i-speed extrusion ikhawuleza;

2. Uboya bokukhutshwa okanye izixhobo azicocekanga;

3. Ioli yokungunda;

4. Uyilo olungafanelekanga lokubumba, ukungonelanga okanye ukungalingani kwe-hydrostatic yoxinzelelo, uyilo olungenangqiqo lwemingxuma ye-shunt;

5. Kukho i-oil stain phezu kwe-ingot.

Indlela yokuthintela

1. Ukwandisa ngokufanelekileyo i-coefficient ye-extrusion, ukushisa kwe-extrusion kunye ne-extrusion speed;

2. Uyilo olufanelekileyo kunye nokuveliswa kokungunda;

3. I-cylinder ye-extrusion kunye ne-extrusion gasket ayinamafutha kwaye igcinwe icocekile;

4. Sebenzisa iingots ezinendawo ecocekileyo.

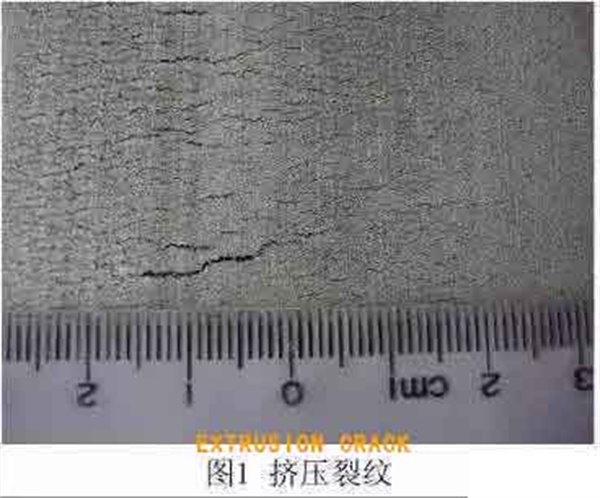

V. Iintanda ze-Extrusion

Oku kukuqhekeka okuncinci okwe-arc kumda wesiqwenga sovavanyo olunqamlezayo lwemveliso ekhutshiweyo, kunye nokuqhekeka kwamaxesha kwi-engile ethile ecaleni kwendlela yayo yobude, efihliweyo phantsi kwe-epidermis kwiimeko ezikhanyayo, kunye neentanda ze-serrated kumaleko angaphandle. kwiimeko ezinzima, eziya kulimaza kakhulu ukuqhubeka kwesinyithi.Ukuqhekeka kwe-Extrusion kwenziwa xa umphezulu wesinyithi ukrazulwa kuxinzelelo olugqithileyo lwexesha lokuxinana kodonga lokufa ngexesha lenkqubo ye-extrusion.

Oyena nobangela wokuqhekeka kwe-extrusion

1. Isantya se-extrusion sikhawuleza kakhulu;

2. Ubushushu bokukhutshwa buphezulu kakhulu;

3. Isantya se-extrusion siguquguquka kakhulu;

4. Ubushushu boboya obukhutshiweyo buphezulu kakhulu;

5. Xa i-porous die extruded, ilungiselelo lokufa lisondele kakhulu kwiziko, ukwenzela ukuba ukunikezelwa kwentsimbi ephakathi kunganelanga, ukwenzela ukuba umehluko phakathi kweziko kunye nesantya sokuhamba komphetho mkhulu kakhulu;

6. I-ingot homogenization annealing ayilungile.

Indlela yokuthintela

1. Ukuphumeza ngokungqongqo imilinganiselo eyahlukeneyo yokufudumeza kunye ne-extrusion;

2. Ukuhlolwa rhoqo kwezixhobo kunye nezixhobo zokuqinisekisa ukusebenza okuqhelekileyo;

3. Lungisa uyilo lokubumba kwaye uluqhube ngononophelo, ngakumbi uyilo lwebhulorho yokubumba, igumbi le-welding kunye ne-edge radius, njl.

4. Ukunciphisa umxholo we-sodium kwi-alloys ye-aluminium ephezulu ye-magnesium;

5. I-ingot i-homogenized kwaye ifakwe i-anneal ukuphucula iplastiki kunye nokufana kwayo.

VI.Amaqamza

Isinyithi sesikhumba sendawo sihlala sihlukana ngokuqhubekayo okanye ngokungaqhubekiyo kwisiseko sesinyithi, kwaye sibonakaliswa njengesetyhula enye okanye i-striped-shaped cavity lifted defect, ebizwa ngokuba yi-bubble.

Oyena nobangela wamaqamza

1. Xa i-extruding, i-cylinder extrusion kunye ne-extrusion pad inokungcola njengomswakama kunye neoli;

2. Ngenxa yokugqoka i-cylinder ye-extrusion, umoya phakathi kwendawo egugileyo kunye ne-ingot ingena kwi-metal surface ngexesha lokukhupha;

3. Kukho ukufuma kwi-lubricant;

4. Isakhiwo se-ingot ngokwaso sineziphene ezikhululekile kunye ne-porosity;

5. Iqondo lokushisa lokushisa liphezulu kakhulu, ixesha lokubamba lide kakhulu, kwaye umswakama we-atmosphere kwisithando somlilo uphezulu;

6. Umxholo we-hydrogen kwimveliso uphezulu kakhulu;

7. Extrusion cylinder ubushushu kunye nobushushu ingot kakhulu.

Indlela yokuthintela

1. Umphezulu wezixhobo kunye neengots kufuneka zigcinwe zicocekile, zigudile kwaye zomile;

2. Ukuyila ngokufanelekileyo ubungakanani obuhambelanayo be-cylinder ye-extrusion kunye ne-gasket ye-extrusion, khangela ubungakanani besixhobo rhoqo, lungisa i-cylinder ye-extrusion ngexesha xa kukho isisu esikhulu, kwaye i-gasket ye-extrusion ayifanele ibe ngaphandle kokunyamezela;

3. Qinisekisa ukuba i-lubricant icocekile kwaye yomile;

4. Ukuthobela ngokungqongqo inkqubo yokusebenza kwenkqubo ye-extrusion, ukukhupha ngexesha, ukusika ngokuchanekileyo, ungasebenzisi ioli, ukususa ngokupheleleyo izinto ezishiyekileyo, gcina izikhala kunye nezibunjwa zicocekile kwaye zingangcoliswa.

VII.Ukuxobula

Le yimeko yokuhlukana kwendawo phakathi kwentsimbi yesikhumba kunye nesiseko sesinyithi semveliso ye-aluminium alloy extrusion.

Oyena nobangela wokuxobula

1. Xa i-alloy ithathelwa indawo kwaye ikhutshwe, udonga lwangaphakathi lwe-cylinder extrusion lunamathele kwihlathi elenziwe yintsimbi yokuqala, engacocwanga ngokufanelekileyo;

2. I-cylinder ye-extrusion kunye ne-extrusion pad ayihambelani ngokufanelekileyo, kwaye udonga lwangaphakathi lwe-cylinder ye-extrusion lufakwe ngetsimbi yendawo yokuhlala;

3. Ikhutshwe nge-lubricating extrusion cylinder;

4. Kukho isinyithi kumngxuma wokufa okanye ibhanti elisebenzayo ledayi lide kakhulu.

Indlela yokuthintela

1. Ukucoca ngokucokisekileyo i-cylinder extrusion xa ukhupha i-alloy;

2. Ukuyila ngokufanelekileyo ubungakanani obuhambelanayo be-cylinder ye-extrusion kunye ne-gasket ye-extrusion, khangela ubungakanani besixhobo rhoqo, kwaye i-gasket ye-extrusion ayikwazi ukunyamezela;

3. Coca intsimbi eshiyekileyo kumngundo ngexesha.

VIII.Imikrwelo

Izibazi zoomatshini ezinomgca omnye ezibangelwa ukudibana phakathi kwezinto ezibukhali kunye nomphezulu wemveliso ngexesha lokutyibilika kwesalamane kuthiwa yimikrwelo.

Oyena nobangela wemikrwelo

1. Ukuhlanganiswa okungafanelekanga kwezixhobo, izikhokelo ezingabonakaliyo kunye neetafile zokusebenza, iikona ezibukhali okanye izinto zangaphandle, njl.;

2. Kukho iitshiphu zetsimbi kwi-mold work belt okanye i-mold work belt yonakaliswe;

3. Kukho isanti okanye iitshiphu zetsimbi ezaphukileyo kwioli yokuthambisa;

4. Ukusebenza okungafanelekanga ngexesha lokuthutha kunye ne-spreader engafanelekanga.

Indlela yokuthintela

1. Jonga kwaye upolishe ibhanti lokungunda ngexesha;

2. Khangela umjelo wokuphuma kwemveliso, kufuneka ihambe kakuhle, kwaye umzila wesikhokelo unokuthanjiswa ngokufanelekileyo;

3. Thintela ukuhlikihla ngoomatshini kunye nokukrwela ngexesha lokuphatha.

IX.Amaqhuma

Amanxeba akhiwe kumphezulu weemveliso okanye iimveliso ezingqubane nezinye izinto zibizwa ngokuba ngamaqhuma.

Oyena nobangela wamaqhuma

1. Isakhiwo sebhentshi yokusebenzela kunye ne-rack material ayinangqiqo;

2. Ukukhuselwa kwesinyithi okungafanelekanga kweebhasikithi eziphathekayo, ii-racks eziphathekayo, njl.;

3. Musa ukuyiphatha ngenkathalo xa usebenza.

Indlela yokuthintela

1. Ukusebenza ngononophelo, phatha ngononophelo;

2. Gaya iikona ezibukhali, kwaye ugubungele ibhasikidi kunye ne-rack kunye ne-dunnage kunye nezinto ezithambileyo.

X. Imikrwelo

Izibonda ezisasazwe kwimiqulu kumphezulu wemveliso ezibangelwa ukutyibilika okanye ukuchithwa kwesalamane emva kokuba umphezulu wemveliso ekhutshiweyo udibane nemiphetho okanye imiphezulu yezinye izinto ibizwa ngokuba yimikrwelo.

Oyena nobangela wemikrwelo

1. Umngundo ugugile kakhulu;

2. Ngenxa yokushisa okuphezulu kwe-ingot, umgodi wokufa unamathela kwi-aluminium okanye ibhanti elisebenzayo lomngxuma wokufa lonakaliswe;

3. Ukungcola okufana negraphite kunye neoli ziwela kwi-cylinder extrusion;

4. Iimveliso zihamba kunye nomnye, ukwenzela ukuba umphezulu uhlanjululwe kwaye ukuhamba kwe-extrusion kungalingani, okubangela ukuba iimveliso zingaphumi kumgca ochanekileyo, okubangelwa imikrwelo phakathi kwezinto kunye nesikhokelo kunye ne-worktable.

Indlela yokuthintela

1. Qwalasela kwaye ubeke endaweni yokubumba engafanelekanga ngexesha;

2. Lawula ubushushu bobushushu boboya;

3. Qinisekisa ukuba umphezulu we-cylinder we-extrusion kunye noboya bucocekile kwaye bomile;

4. Lawula isantya se-extrusion ukuqinisekisa isantya esifanayo.

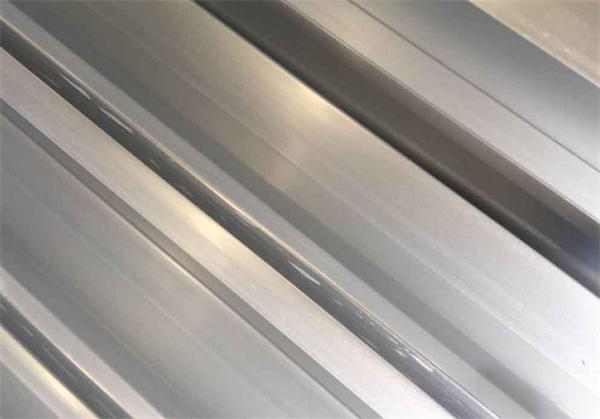

XI.Iimpawu zokungunda

Oku kukulandela ukungalingani kwe-longitudinal kumphezulu wemveliso ekhutshiweyo, kwaye zonke iimveliso ezikhutshiweyo zineempawu zokufa ukuya kumaqondo ahlukeneyo.

Oyena nobangela weempawu zokungunda

Esona sizathu siphambili: ibhanti yokusebenza komngundo ayinakufezekisa ukugudisa ngokupheleleyo.

Indlela yokuthintela

1. Qinisekisa ukuba umphezulu webhanti yokubumba icocekile, igudileyo kwaye ayinamacangca abukhali;

2. Unyango lwe-nitriding olunengqiqo ukuqinisekisa ubunzima obuphezulu bomhlaba;

3. Lungisa ngokuchanekileyo isikhunta;

4. Ibhande elisebenzayo kufuneka lenziwe ngokufanelekileyo, kwaye ibhanti elisebenzayo akufanele libe lide kakhulu.

XII.Jija, jika, wangawangisa

Isenzeko apho icandelo lomnqamlezo wemveliso ekhutshiweyo liphambukiswe nge-angularly kwi-longitudinal direction ibizwa ngokuba yi-twisting.Isenzeko sokuba imveliso igobile kwicala le-longitudinal okanye imilo yemela ayithe tye ibizwa ngokuba kukugoba.Into eqhubekayo engapheliyo eyenzeka kwi-longitudinal direction yemveliso ibizwa ngokuba yi-wave.

Oonobangela abaphambili bokujijeka, ukugoba, kunye namaza

1. Uyilo kunye nokulungiswa kwemingxuma yokufa ayilungile, okanye ukusabalalisa ubungakanani bebhanti yokusebenza akunangqiqo;

2. Ukuchaneka kakubi komatshini kwimingxuma yokufa;

3. Isikhokelo esifanelekileyo asifakwanga;

4. Ukulungiswa kokungunda okungafanelekanga;

5. Ukushisa okungafanelekanga kwe-extrusion kunye nesantya;

6. Imveliso ayilungiswanga kwangaphambili ngaphambi kokuba unyango lwesisombululo;

7. Ukupholisa okungafaniyo ngexesha lonyango lobushushu kwi-intanethi.

Indlela yokuthintela

1. Inqanaba eliphezulu loyilo lokungunda kunye nokuveliswa;

2. Faka isikhokelo esifanelekileyo, ukutsala kunye ne-extrusion;

3. Sebenzisa i-lubrication yendawo, ukulungiswa kwesikhunta kunye nokuguqulwa okanye utshintshe uyilo lomngxuma we-shunt ukulungelelanisa izinga lokuhamba kwesinyithi;

4. Ukulungelelanisa ngokufanelekileyo ukushisa kwe-extrusion kunye nesantya ukwenza i-deformation ibe yinto efanayo;

5. Ukunciphisa ngokufanelekileyo ubushushu bonyango lwesisombululo okanye ukwandisa ubushushu bamanzi kunyango lwesisombululo;

6. Qinisekisa ukupholisa okufanayo ngexesha lokucima i-intanethi.

XIII.Ukugoba okunzima

Ukugoba ngokukhawuleza kwemveliso ekhutshiweyo kwindawo yobude kubizwa ngokuba yi-bend eqinile.

Oyena nobangela wokugoba nzima

1. Isantya esingalinganiyo sokukhupha isantya, ukuguquka ngesiquphe ukusuka kwisantya esisezantsi ukuya kwisantya esiphezulu, okanye ukuguquka ngesiquphe ukusuka kwisantya esisezantsi ukuya kwisantya esisezantsi, kunye nokuma ngesiquphe;

2. Hambisa ngokungqongqo imveliso ngexesha lenkqubo extrusion;

3. Indawo yokusebenza ye-extruder ayilingani.

Indlela yokuthintela

1. Musa ukuma ngokungalindelekanga okanye utshintshe isantya sokukhupha ngokukhawuleza;

2. Musa ukuhambisa iprofayili ngokukhawuleza ngesandla;

3. Qinisekisa ukuba itafile yokukhupha i-flat kunye ne-discharge roller table ilula, ngaphandle kwezinto zangaphandle, kwaye imveliso edibeneyo ayithinteki.

XIV.Iinoodle zeHemp

Esi siphene somgangatho wemveliso ekhutshiweyo, oku kuthetha ukuba umphezulu wemveliso i-flakes eqhubekayo, imikrwelo yamabala, imigodi, iimbotyi zetsimbi, njl njl kunye nokungalingani okuncinci.

Oyena nobangela wepockmark

1. Ubunzima besikhunta akwanelanga okanye ubunzima abulingani;

2. Ubushushu bokukhutshwa buphezulu kakhulu;

3. Isantya se-extrusion sikhawuleza kakhulu;

4. Ibhande elisebenzayo le-mold lide kakhulu, lilukhuni okanye linamathele ngetsimbi;

5. Uboya obukhutshiweyo bude kakhulu.

Indlela yokuthintela

1. Ukuphucula ukuqina kunye nobunzima obufanayo bebhanti yokusebenza komngundo;

2. Ukushisa i-cylinder ye-extrusion kunye ne-ingot ngokwemigaqo, kwaye usebenzise isantya esifanelekileyo sokukhupha;

3. Yila ngokufanelekileyo isikhunta, ukunciphisa uburhabaxa bomphezulu bebhanti yokusebenza, kwaye uqinise ukuhlolwa kwendawo, ukulungiswa kunye nokupholisha;

4. Sebenzisa ubude be-ingot obufanelekileyo.

XV.Ukucofa isinyithi

Ngethuba lenkqubo yokukhupha, iitshiphu zetsimbi zixinzelelwe kumphezulu wemveliso, ebizwa ngokuba yintsimbi.

Izizathu eziphambili zokungena kwentsimbi:

1. Iziphelo zoboya ziphosakele;

2. Umgangatho wangaphakathi woboya unamathele ngentsimbi okanye ioli yokuthambisa iqulethe i-debris yesinyithi kunye nolunye ukungcola;

3. I-cylinder ye-extrusion ayicocwa, kwaye kukho ezinye i-debris zetsimbi;

4. I-ingot ifakwe kwezinye izinto zesinyithi zangaphandle;

5. Kukho ukufakwa kwe-slag eboyeni.

Indlela yokuthintela

1. Susa iintsimbi eboyeni;

2. Qinisekisa ukuba umphezulu woboya kunye ne-oyile yokuthambisa zicocekile kwaye zomile;

3. Coca i-debris yensimbi kwi-mold kunye ne-extrusion cylinder;

4. Khetha uboya obukumgangatho ophezulu.

XVI.Non-metal pressing

Izinto zangaphandle ezifana nelitye elimnyama licinezelekile kwindawo yangaphakathi nangaphandle yemveliso ekhutshiweyo, ebizwa ngokuba yi-non-metallic indentation.Emva kokuba umcimbi wangaphandle ucinywe, umgangatho wangaphakathi wemveliso uya kubonisa ukudandatheka kobukhulu obuhlukeneyo, okuya kutshabalalisa ukuqhubeka kobuso bemveliso.

Oyena nobangela wokungena kwentsimbi

1. Ubungakanani be-particle yegraphite i-coarse okanye i-agglomerated, iqulethe umswakama okanye ioli, kwaye ukuvuselela akulingani;

2. I-flash point yeoli ye-cylinder iphantsi;

3. Umlinganiselo weoli ye-cylinder kunye negraphite ayifanelekanga, kwaye kukho igraphite eninzi.

Indlela yokuthintela

1. Sebenzisa igraphite esemgangathweni kwaye uyigcine yomile;

2. Hlunga kwaye usebenzise ioyile yokuthambisa efanelekileyo;

3. Lawula umlinganiselo weoli yokuthambisa kunye negraphite.

XVII.Umhlwa phezu komhlaba

Iimveliso ezigqithisiweyo ezingakhange zenziwe kunyango lwe-surface, umphezulu wemveliso ekhutshweyo, emva kwekhemikhali okanye i-electrochemical reaction kunye ne-medium yangaphandle, ibangela isiphene esibangelwa ngumonakalo wendawo yendawo, ebizwa ngokuba yi-surface corrosion.Umphezulu wemveliso ebolileyo ulahlekelwa yintsimbi, kwaye kwiimeko ezinzima, iimveliso ze-corrosion grey-white ziveliswa phezu komhlaba.

Oyena nobangela wokubola komphezulu

1. Imveliso ibonakaliswe kumajelo atshabalalisayo njengamanzi, i-asidi, i-alkali, ityuwa, njl njl ngexesha lokuvelisa, ukugcinwa kunye nokuthutha, okanye ipakishwe kwindawo epholileyo ixesha elide;

2. Umlinganiselo ongafanelekanga we-alloy composition;

Indlela yokuthintela

1. Gcina umgangatho wemveliso kunye nemveliso kunye nendawo yokugcina icocekile kwaye yomile;

2. Lawula umxholo wezinto kwi-alloy.

XVIII.I-Orenji peel

Umphezulu wemveliso ekhutshiweyo unemibimbi engalinganiyo efana nexolo leorenji, ekwabizwa ngokuba yimibimbi engaphezulu.Ibangelwa ziinkozo ezirhabaxa ngexesha le-extrusion.Okukhona iinkozo ziba rhabaxa, kokukhona kubonakala imibimbi.

Oyena nobangela we-orange peel

1. Isakhiwo se-ingot asilingani kwaye unyango lwe-homogenization alunelanga;

2. Iimeko ze-extrusion azinangqiqo, kwaye iinkozo zeemveliso ezigqityiweyo zilukhuni;

3. Ubungakanani bokwelula kunye nokulungelelanisa bukhulu kakhulu.

Indlela yokuthintela

1. Ukulawula ngokufanelekileyo inkqubo ye-homogenization;

2. I-deformation kufuneka ifane ngokusemandleni (ukulawula ukushisa kwe-extrusion, isantya, njl.)

3. Lawula ubungakanani bolungiso loxinzelelo ukuba lungabi lukhulu kakhulu.

XIX.Ukungalingani

Emva kwe-extrusion, indawo apho ubukhulu bemveliso buguqukayo kwindiza ibonakala i-concave okanye i-convex.Ngokuqhelekileyo, ayinakubonwa ngeso lenyama.Emva kokunyanga kwendawo, izithunzi ezintle okanye izithunzi zamathambo zivela.

Oyena nobangela wokungalingani

1. Ibhanti esebenzayo yokubumba ayilungiswanga ngokufanelekileyo, kwaye ukulungiswa kwesikhunta akukho ndawo;

2. Ubungakanani bomngxuma we-shunt okanye i-pre-chamber ayifanelekanga, kwaye amandla okutsala okanye ukwandisa iphrofayili kwindawo yesiphambano kubangela utshintsho oluncinci kwindiza;

3. Inkqubo yokupholisa ayilingani, kwaye isantya sokupholisa senxalenye enodonga olungqingqwa okanye i-intersecting part iyacotha, okukhokelela kwiidigri ezihlukeneyo zokucutheka kunye nokuguqulwa kwendiza ngexesha lenkqubo yokupholisa;

4. Ngenxa yomahluko omkhulu kubunzima, umahluko phakathi kwenxalenye engqingqwa okanye intlangano yendawo yenguqu kunye nezinye iindawo zombutho zanda.

Indlela yokuthintela

1. Ukuphucula umgangatho woyilo lokungunda, ukwenziwa kunye nokulungiswa kokungunda;

2. Qinisekisa isantya sokupholisa esifanayo.

XX.Ipateni yokungcangcazela

Esi sisiphene se-periodic streak transverse ukuya kumphezulu wemveliso ekhutshiweyo.Ibonakaliswa yimivimbo ethe tye eqhubekayo ejikelezayo kumphezulu wemveliso, kwaye igophe lomgca lihambelana nokumila kwebhanti elisebenzayo lokungunda, kwaye kwiimeko ezinzima, kukho ukuvakalelwa okucacileyo kwe-bumpy.

Oyena nobangela wokungcangcazela

1. I-shaft extrusion ihamba phambili kwaye ishukunyiswa ngenxa yezizathu zezixhobo, ezibangela ukuba isinyithi sishukume xa siphuma emngxunyeni;

2. Intsimbi iyashukuma xa iphuma kumngxuma wokufa ngenxa yokungunda;

3. I-pad yokuxhasa i-mold ayifanelekanga, i-mold rigidity ayilungile, kwaye i-vibration iyenzeka xa i-extrusion force iguquguquka.

Indlela yokuthintela

1. Sebenzisa iimolds ezifanelekileyo;

2. Iipads zokuxhasa ezifanelekileyo kufuneka zisetyenziswe xa i-mold ifakwe;

3. Lungisa izixhobo.

XXI, Mixed

Unobangela ophambili wokubandakanywa

Ekubeni i-billet yokubandakanywa inentsimbi okanye i-non-metal inclusions, ayizange ifumaneke kwinkqubo yangaphambili, kwaye yahlala phezu komhlaba okanye ngaphakathi kwemveliso emva kokuphuma.

Indlela yokuthintela

Ukuqinisa ukuhlolwa kwe-billet (kubandakanywa nokuhlolwa kwe-ultrasonic) ukukhusela i-billet equkethe i-metal okanye i-non-metallic inclusions ekungeneni kwinkqubo yokukhupha.

XXII, Amanqaku amanzi

Iimpawu ezimhlophe ezimhlophe okanye ezimnyama ezingaqhelekanga zomgca wamanzi kumphezulu wemveliso zibizwa ngokuba ziimpawu zamanzi.

Oyena nobangela weempawu zamanzi

1. Ukomisa akulungile emva kokucoca, kwaye kukho umswakama oseleyo phezu komgangatho wemveliso;

2. Ukufuma okushiyekileyo kumphezulu wemveliso obangelwa yimvula kunye nezinye izizathu azihlambulukanga ngexesha;

3. I-fuel of the furnace yokuguga iqulethe amanzi, kwaye amanzi adibanisa phezu kwemveliso ngexesha lokupholisa imveliso emva kokuguga;

4. I-fuel of the furnace eguga ayihlambulukanga, kwaye ubuso bemveliso buhlanjululwe yi-sulfure dioxide emva kokutsha okanye ukungcoliswa kothuli;

5. Isixhobo sokucima singcolile.

Indlela yokuthintela

1. Gcina ubuso bemveliso bomile kwaye bucocekile;

2. Lawula umxholo wokufuma kunye nokucoceka kwentlawulo yokuguga;

3. Ukuqinisa ulawulo lwesixhobo sokucima.

XXIII.Umsantsa

Umlawuli ubekwe ngokuthe tye kwiplani ethile yemveliso ekhutshiweyo, kwaye kukho umsantsa othile phakathi komlawuli kunye nomphezulu, obizwa ngokuba yi-gap.

Oyena nobangela wesisantsa

Ukuhamba kwentsimbi engalinganiyo ngexesha lokukhupha okanye ukugqiba ngokungafanelekanga kunye nokusebenza ngokuthe ngqo.

Indlela yokuthintela

Yila kwaye wenze iimbumba ngokufanelekileyo, ukuqinisa ukulungiswa kwesikhunta, kunye nokulawula ubushushu bokushisa kunye nesantya sokukhupha ngokuhambelana ngqongqo nemimiselo.

XXIV, Ubunzima bodonga olungalinganiyo

Iimveliso ezikhutshiweyo zobukhulu obufanayo zineendonga ezinqabileyo okanye ezingqingqwa kwinqanaba elifanayo okanye ulwalathiso lwe-longitudinal, kwaye isenzeko sibizwa ngokuba ngudonga olungalinganiyo.

Oyena nobangela wobunzima bodonga olungalinganiyo

1. Uyilo lokubumba alunangqiqo, okanye isixhobo kunye nendibano yokubumba ayifanelekanga;

2. I-cylinder ye-extrusion kunye nenaliti ye-extrusion ayikho kwinqanaba elifanayo, lenza i-eccentricity;

3. I-lining ye-cylinder ye-extrusion igqitywe kakhulu, kwaye i-mold ayikwazi ukuqiniswa ngokuqinileyo, ibangele u-eccentricity;

4. Ubunzima bodonga olungalinganiyo lwe-ingot blank ngokwayo abukwazi ukupheliswa emva kwe-extrusions yokuqala neyesibini.Ubunzima bodonga olungalinganiyo loboya emva kokukhutshwa abususwanga emva kokuqengqeleka kunye nokwelula;

5. Ioli yokuthambisa isetyenziswe ngokungafaniyo, eyenza ukuba isinyithi sihambe ngokungalingani.

Indlela yokuthintela

1. Ukwandisa uyilo kunye nokuveliswa kwezixhobo kunye nokubumba, kwaye udibanise ngokufanelekileyo kwaye ulungelelanise;

2. Lungisa iziko le-extruder kunye ne-extrusion die;

3. Khetha izikhewu ezivunyiweyo;

4. Ulawulo olufanelekileyo lobushushu be-extrusion, isantya se-extrusion kunye nezinye iiparamitha zenkqubo.

XXV.Yandisa (kunye) nomlomo

Isiphene sokuba amacala amabini emveliso yeprofayili ekhutshiweyo njengegroove kunye ne-I-shaped athambekele ngaphandle kuthiwa yi-flaring, kwaye isiphene esithambekele ngaphakathi sibizwa ngokuba yi-parallel opening.

Oyena nobangela wokwandiswa (ukuhlanganiswa)

1. Isantya sokuhamba kwesinyithi "yemilenze" emibini (okanye "umlenze" omnye) wesitya okanye iiprofayili ezifanayo okanye iiprofayili ze-I-shaped;

2. Isantya sokuhamba kwebhanti yokusebenza kumacala omabini eplate ephantsi ye-groove ayilingani;

3. Umatshini wokolula ongafanelekanga;

4. Emva kokuba imveliso iphumile kumngxuma wokubumba, unyango lwesisombululo se-intanethi lupholile ngokulinganayo.

Indlela yokuthintela

1. Lawula ngokungqongqo isantya se-extrusion kunye nobushushu be-extrusion;

2. Qinisekisa ukufana kokupholisa;

3. Yila ngokuchanekileyo kwaye wenze imibumba;

4. Lawula ngokungqongqo ubushushu be-extrusion kunye nesantya, kwaye ufake isixhobo kwaye ufe ngokuchanekileyo.

XXVI.Amanqaku olula

I-helical streaks eveliswayo xa umqulu ophezulu wemveliso ekhutshiweyo uchanekileyo ubizwa ngokuba yimpawu ezichanekileyo, kwaye iimpawu ezichanekileyo azinakugwenywa kuyo nayiphi na imveliso eqondiswe ngumqulu ophezulu.

Oyena nobangela wamanqaku okuqondisa

1. Kukho imiphetho kwi-roller surface ye-roller yokuqondisa;

2. Ukugoba kwemveliso kukhulu kakhulu;

3. Uxinzelelo olukhulu;

4. I-angle ye-roller yokuqondisa inkulu kakhulu

5. Imveliso ine-ovality enkulu.

Indlela yokuthintela

Thabatha amanyathelo afanelekileyo okuhlengahlengisa ngokwesizathu.

XXVII.Ukuyeka amanqaku, ukubonakala ngokukhawuleza, amanqaku okuluma

Misa i-extrusion ngexesha lokukhupha ukuvelisa imivimbo ebusweni bemveliso kunye ne-perpendicular ukuya kwi-extrusion direction direction, ebizwa ngokuba yi-stop marks;Umgca okanye imigca yemigca kumphezulu wemveliso kunye ne-perpendicular ukuya kwicala le-extrusion ngexesha lokukhupha, eyaziwa ngokuba ngamanqaku okuluma okanye ukubonakala kwangoko (ekwaziwa ngokuba "ziimpawu zokupaka zomgunyathi")

Ngexesha lokukhutshwa, iziqhotyoshelo ezinamathele ngokuzinzile kumphezulu webhanti esebenzayo zikhutshwe ngokukhawuleza kwaye zinamathele kumphezulu wemveliso ekhutshiweyo ukwenza iipatheni.Imivimbo ethe tyaba yebhanti yokusebenza ebonakalayo xa i-extrusion imisiwe ibizwa ngokuba ngamanqaku okupaka;imivimbo ebonakala ngexesha lenkqubo ye-extrusion ibizwa ngokuba yi-instant impressions okanye i-bite marks, kwaye baya kwenza isandi ngexesha le-extrusion.

Oonobangela abaphambili bamanqaku okuyeka, amanqaku akhawulezileyo, kunye namanqaku okuluma

1. Ukushisa okungafaniyo kokufudumeza kwe-ingot okanye utshintsho olukhawulezayo kwisantya sokukhupha kunye noxinzelelo;

2. Iinxalenye eziphambili zesikhunta ziyilwe kakubi kwaye zenziwe, okanye indibano ayilingani kwaye kukho izikhewu;

3. Kukho amandla angaphandle e-perpendicular ukuya kwi-extrusion direction direction;

4. I-extruder ayiqhubeki kakuhle, kwaye kukho isenzeko sokukhasa.

Indlela yokuthintela

1. Ubushushu obuphezulu, isantya esicothayo kunye ne-extrusion efanayo, i-extrusion force ihlala izinzile;

2. Ukuthintela amandla angaphandle kwi-vertical extrusion direction ukusuka ekusebenzeni kwimveliso;

3. Uyilo olunengqiqo lwezixhobo kunye nokubumba, ukhetho oluchanekileyo lwezinto zokubumba, ukulinganisa ubungakanani, amandla kunye nobunzima.

XXVIII.Imikrwelo kumphezulu wangaphakathi

Imikrwelo kwindawo yangaphakathi yemveliso ekhutshiweyo ngexesha lenkqubo ye-extrusion ibizwa ngokuba yimikrwelo yangaphakathi yangaphakathi.

Oyena nobangela wokuqhawuka komphezulu wangaphakathi

1. Inaliti ye-extrusion ibanjwe ngentsimbi;

2. Ubushushu benaliti ye-extrusion iphantsi;

3. Umgangatho ophezulu wenaliti ye-extrusion umpofu kwaye kukho ama-bumps;

4. Ubushushu be-extrusion kunye nesantya asilawulwa kakuhle;

5. Umlinganiselo ongafanelekanga we-lubricant extrusion;

Indlela yokuthintela

1. Ukwandisa ubushushu be-cylinder ye-extrusion kunye nenaliti ye-extrusion, kwaye ulawule ukushisa kwe-extrusion kunye ne-extrusion speed;

2. Ukuqinisa ukuhluzwa kweoli yokuthambisa, jonga okanye ubuyisele i-oyile yenkunkuma rhoqo, kwaye usebenzise i-oyile ngokulinganayo nangokufanelekileyo;

3. Gcina umphezulu woboya ucocekile;

4. Faka indawo yokubumba engafanelekanga kunye neenaliti zokukhupha ngexesha, kwaye ugcine ubuso be-extrusion molds bucocekile kwaye bugudileyo.

XXX.Ezinye izinto

Ngelizwi, emva konyango olubanzi, iintlobo ezingama-30 zeziphene ezikhankanywe ngasentla ze-aluminium alloy extrusion zinokupheliswa ngokufanelekileyo, umgangatho ophezulu, isivuno esiphezulu, ubomi obude, kunye nomphezulu wemveliso omhle, ukudala uphawu, ukuzisa amandla kunye nokuchuma ishishini, kunye neenzuzo ezibalulekileyo zobugcisa nezoqoqosho.

XXX.Ezinye izinto

Ngelizwi, emva konyango olubanzi, iintlobo ezingama-30 zeziphene ezikhankanywe ngasentla ze-aluminium alloy extrusion zinokupheliswa ngokufanelekileyo, umgangatho ophezulu, isivuno esiphezulu, ubomi obude, kunye nomphezulu wemveliso omhle, ukudala uphawu, ukuzisa amandla kunye nokuchuma ishishini, kunye neenzuzo ezibalulekileyo zobugcisa nezoqoqosho.

Ixesha lokuposa: Aug-14-2022