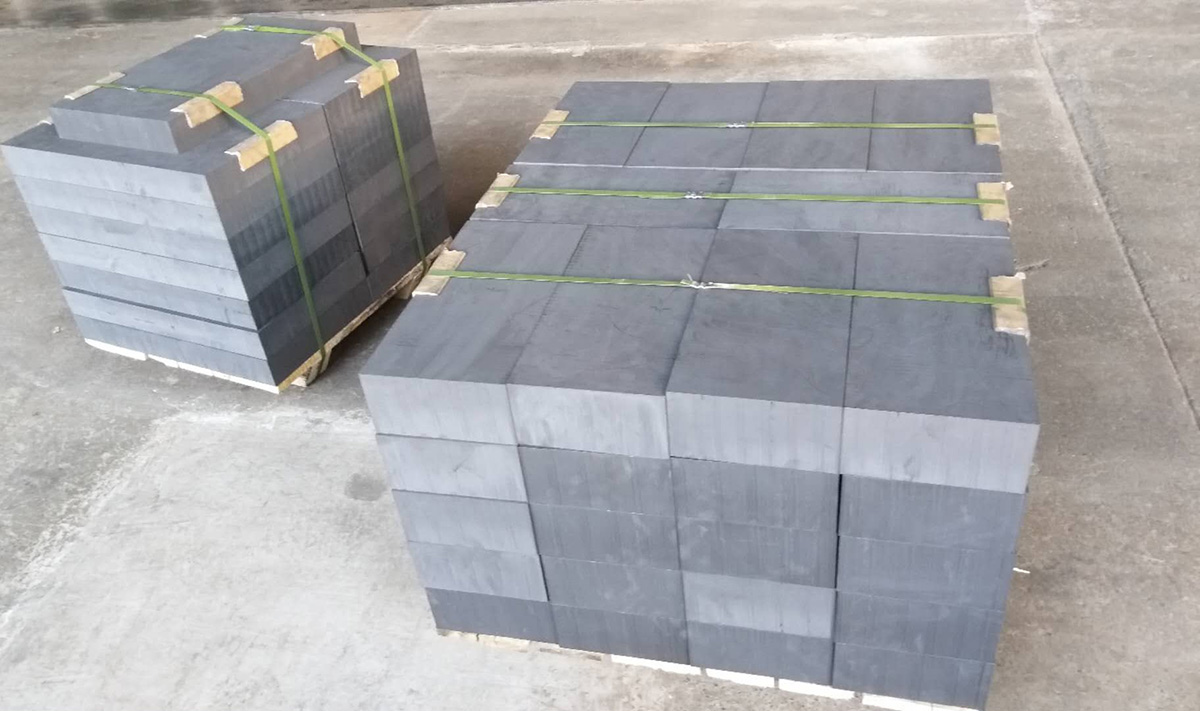

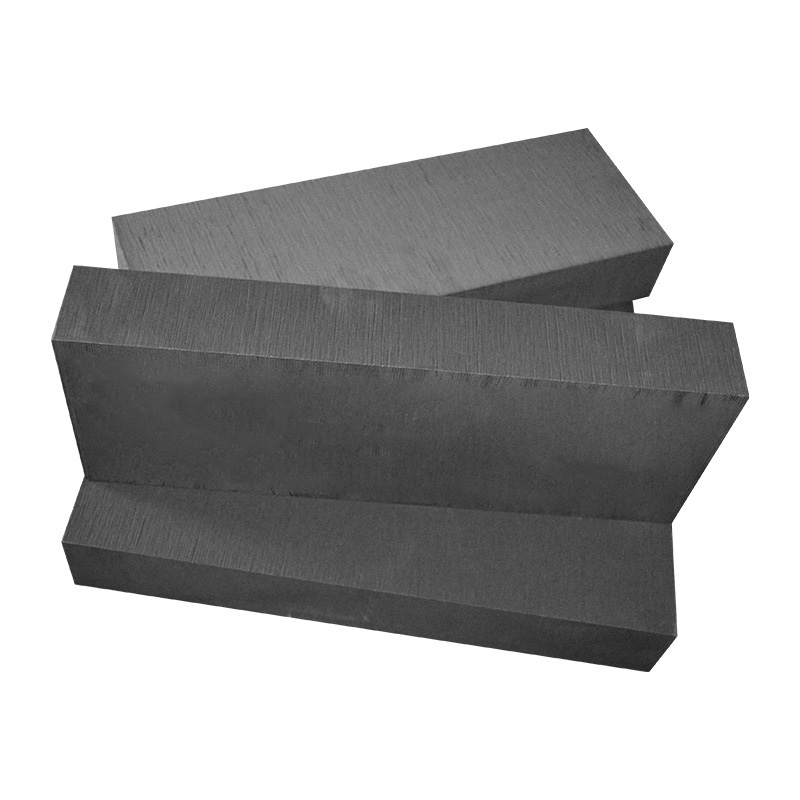

ukuxhathisa umhlwa ipleyiti yegraphite kwiprofayili ye-aluminium extrusion

Ipleyiti yegraphite ekuphumeni komshicileli we-aluminium extrusion idlala indima yokuthambisa.Ngokuqhelekileyo, i-graphite engaphezulu ye-coarse-grained isetyenziswa.Igraphite ecocekileyo ephezulu ilungile kwaye igudileyo, kwaye amathuba okukrwela izinto ze-aluminium zincinci kakhulu.Ukusebenzisa le mathiriyeli yococeko oluphezulu kuya kwandisa kakhulu ubomi benkonzo kunye nokugcina iindleko ngokulinganayo.

Igama lemveliso: Iphepha legraphite yeAluminiyam

Iimpawu zeMveliso: ukusetyenzwa okulungiselelweyo Okukhethekileyo kwimveliso yeemveliso ezahlukeneyo zegraphite, ezinokuthi zenziwe ngokweemfuno zabathengi!

1. Ukuba unemizobo, nceda uthumele imidwebo (i-CAD, i-PDF, imidwebo yezandla).

2. Cacisa ubungakanani, ubungakanani, ubukhulu, njl.

3. Ukumisela iteknoloji yokucubungula (ukusika okulula, ukubethelwa, iinxalenye ze-heterosexual ezenziwe ngokwezifiso, ukugaya, ukugaya kunye ne-saw cutting, njl.).

4. Intlawulo inokwenziwa emva kwekoteyishini.

Phawula:Ukuba ubungakanani bufunekayo ukuba buchaneke ngokukodwa, nceda uchaze, kuba kuya kubakho ukunyamezela okuthile kwiinkqubo eziqhelekileyo ezifana nokusika, ukugaya kunye nokubetha.Ukuba kukho iimfuno ezichanekileyo zeengxenye ezikhethekileyo, kufuneka zichazwe kwangaphambili.Ukudubula kwengqondo ngononophelo Iimpawu: 1 Ukumelana nobushushu obulungileyo 2 Ukuthambisa kunye nokumelana nokunxiba 3 Ukuqhuba kakuhle kwe-thermal 4 Ukuchaneka kobuchwephesha bokuchaneka kwesiko

|

uhlobo |

Umzekelo |

Ukuxinana (g/cm) | Ukuxhathisa (uQ*m) | I-Thermal conductivity (W/m) | I-coefficient yokwandisa i-Thermal igumbi legumbi-600*C | Ukuqina konxweme (HSD) | Amandla e-Flexural (MPa) | Compressive amandla (MPa) | i-porosity %≤ | Ukutya okuziinkozo (um) |

| Igraphite ebunjiweyo | JL-02 | 1.8 | 8~11 | 125 | 5.46 | 45 | 43 | 75 | 17 | 13–15 |

| JL-04 | 1.85 | 8~10 | 142 | 4.75 | 48 | 46 | 90 | 13 | 13–15 | |

| Igraphite ecinezelwe nge-Isostatic | JL-08 | 1.90 | 8~9 | 140 | 5.1 | 58 | 59 | 98 | 11 | 8~10 |

| IJL-11 | 1.95 | 11-13 | 87 | 5.64 | 76 | 68 | 145 | 11 | 8~10 | |

| JL-12 | 1.68 | 13 | - | - | - | 25 | 50 | - | - | |

| IJL-16 | 1.82 | 14.2 | - | - | 68 | 58 | 118 | 12 | - | |

| JL-17 | 1.85 | 13.5 | - | - | 67 | 65 | 135 | 11 | - | |

| amasuntswana arhabaxa | JL-24 | 1.6 | 9-12 | - | - | >25 | >13 | >22 | - | 0-20.8 |

| amasuntswana amahle | JL-25 | 1.72 | 8~11 | - | - | ≥30 | ≥17 | >30 | - | 0-20.8 |