Kwishishini le-aluminium Foundry, ukusetyenziswa kwe-aluminiyam ye-ceramic launder ukuhambisa i-aluminiyam etyhidiweyo ibalulekile ekuqinisekiseni inkqubo yemveliso egudileyo nesebenzayo.Umtshini we-ceramic owenziwe kakuhle kwaye osebenza kakuhle unokuphucula kakhulu umgangatho we-metallurgical of casting kunye negalelo ekongeni amandla.

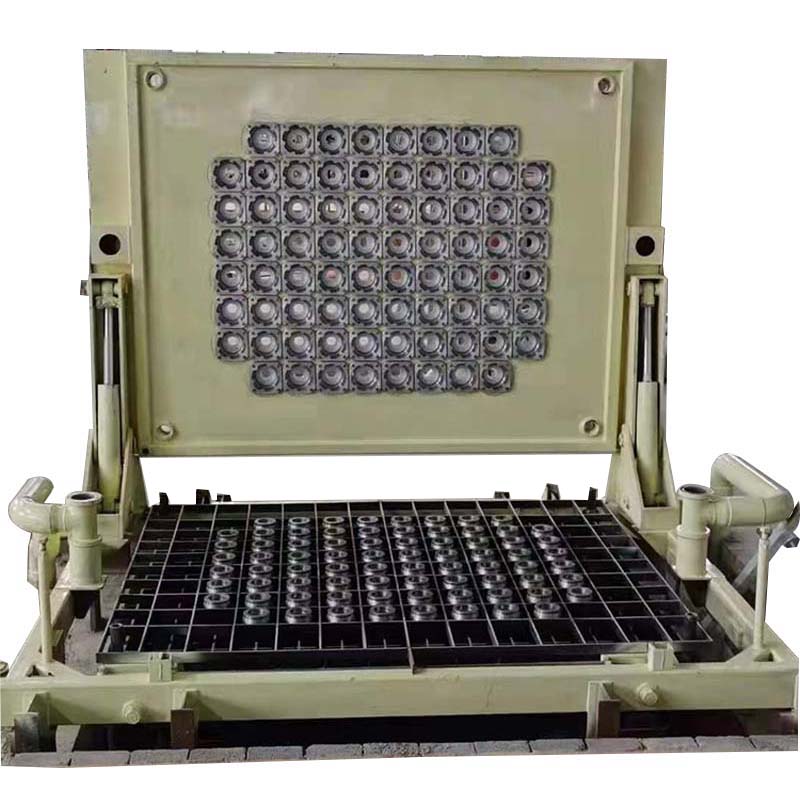

An i-aluminium ceramic launder lijelo elisetyenziselwa ukuhambisa ialuminiyam etyhidiweyo ukusuka kwiziko ukuya kwisingundo sokuphosa.Idlala indima ebalulekileyo ekugcineni ingqibelelo ye-aluminium engamanzi kunye nokuqinisekisa ukuba ifikelela kubumba.Uyilo kunye nokwakhiwa komtshini we-ceramic kubalulekile ekufezekiseni ezi njongo.

Enye yeenzuzo eziphambili zokusebenzisa i-aluminiyam ye-ceramic launder kwinkqubo yokuphosa amandla ayo okunciphisa ubushushu be-aluminium etyhidiweyo.Ngokuqondisa ulwelo ngokusebenzisa i-launders efakwe kakuhle kunye ne-lined ngokufanelekileyo, ubushushu bunokulawulwa ngcono, ukukhusela ukushisa.Oku kubaluleke kakhulu ekuveliseni i-castings ephezulu eneempawu ezifunwayo.

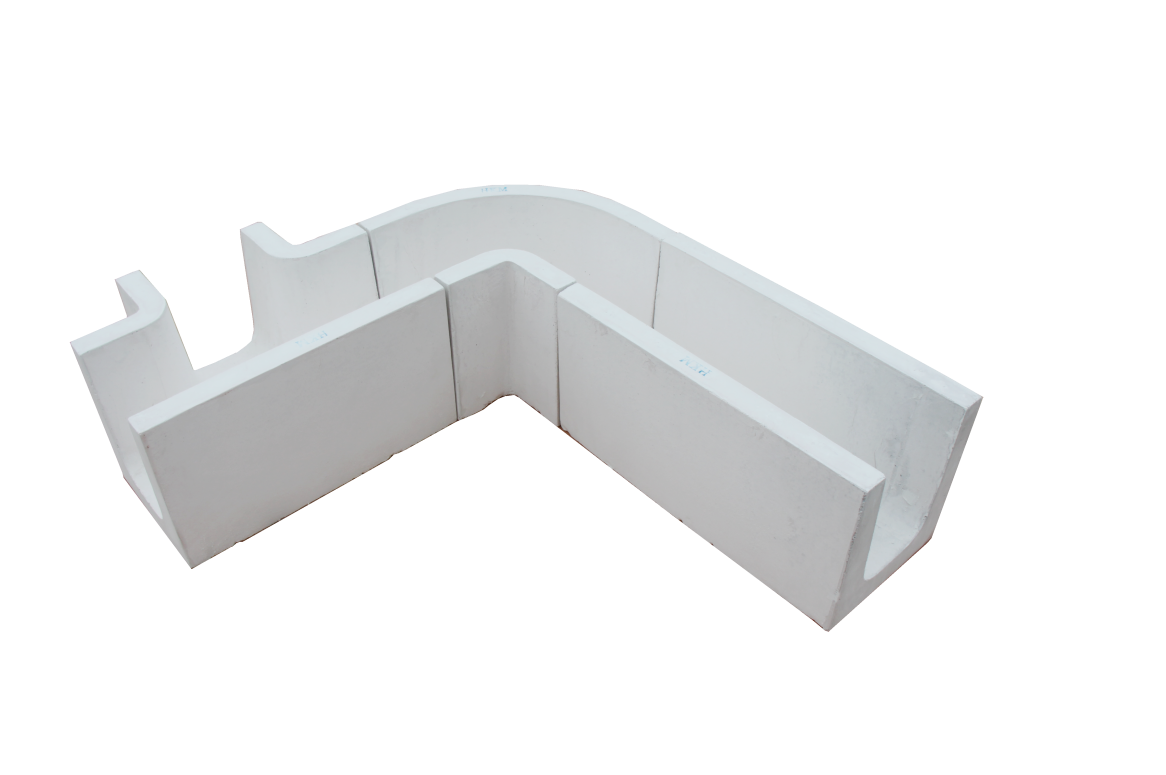

Ngaphaya kwale misebenzi isisiseko, abahlambi be-aluminiyam be-ceramic beza kwiimilo ezahlukeneyo ukuze balungele ukuseta kwesiseko kunye neemfuno.Nokuba i-groove yokuhamba ineemilo ezahlukeneyo ezifana ne-DC groove, i-elbow, i-tee, umnqamlezo njalo njalo, imilo ye-ceramic launder ingaba cu.

stomized ukuhlangabezana neemfuno ezithile zenkqubo yokuphosa.Ukongeza, i-lining ye-launder yenzelwe ukuba ibe nomphezulu ogudileyo, ongeyena nje ukuhambisa ukuhamba kakuhle kwe-aluminium etyhidiweyo, kodwa inegalelo ekuxhathiseni ukothuka kwe-thermal.Oku kubalulekile njengoko ubushushu obungazinzanga bunokubangela iintanda kunye nomonakalo kwisihlambi.

Enye ipropathi ebalulekileyo ye-aluminium ceramic launder bubomi babo benkonzo ende.Izinto ezisetyenzisiweyo ze-lining zikhethwa ngenxa yokuqina kwayo kunye nokukwazi ukumelana neemeko ezinzima ze-Foundry environment.Oku kuqinisekisa ukusebenza ngokufanelekileyo kwexesha elide lokuhlamba impahla, ukunciphisa ixesha lokuphumla kunye neendleko zokugcina.

Ukongeza, izinto zombane ze-aluminium ceramic launder zenziwe ngokukodwa ukuba zinganamatheli kwi-aluminium.Oku kuthetha ukuba i-aluminium etyhidiweyo ayinamathele kwi-liner, le propati engenakunqanda nayo inceda ekuphuculeni umgangatho wokuphosa.Kwiinkqubo yokuphosa phezulu eshushu,

umaleko obhityileyo weumgubo wetalcum kufuneka isasazwe kwindawo yokuhlamba impahla phambi kokuba kutyhilwe, akufuneki kubekho iziqwenga zentsimbi eziveziweyo kunye nomjelo apho i-aluminiyam etyhidiweyo idlula khona kufuneka igcinwe icocekile kwaye yomile, ivumela ukuhamba okugudileyo, okuqhubekayo.

Isishwankathelo, ukusetyenziswa kwe-aluminiyam ye-ceramic launder kwinkqubo yokuphosa i-aluminium ibalulekile ekuhambiseni i-aluminium etyhidiweyo.Ayiphuculi kuphela umgangatho we-metallurgical of castings, kodwa inegalelo ekugcinweni kwamandla.Ikhono lokunciphisa ubushushu be-aluminium etyhidiweyo, ukukhusela izinto ezixutywayo ziinzuzo eziphambili zokusebenzisa i-aluminium ceramic launder.Ngokusebenzisa izinto eziphambili ezinamandla amakhulu, ukumelana nokugqwala kunye nokuxhathisa ukutshatyalaliswa kwe-thermal, i-ceramic launder iqinisekisa ubomi obude benkonzo kunye nokunciphisa ixesha lokuphumla.Ngeempawu zayo ezingezizo, i-ceramic launder iphinda incede ukuthintela ukungcoliswa kunye nokuqinisekisa ukuveliswa kwemigangatho ephezulu.

Ixesha lokuposa: Aug-16-2023