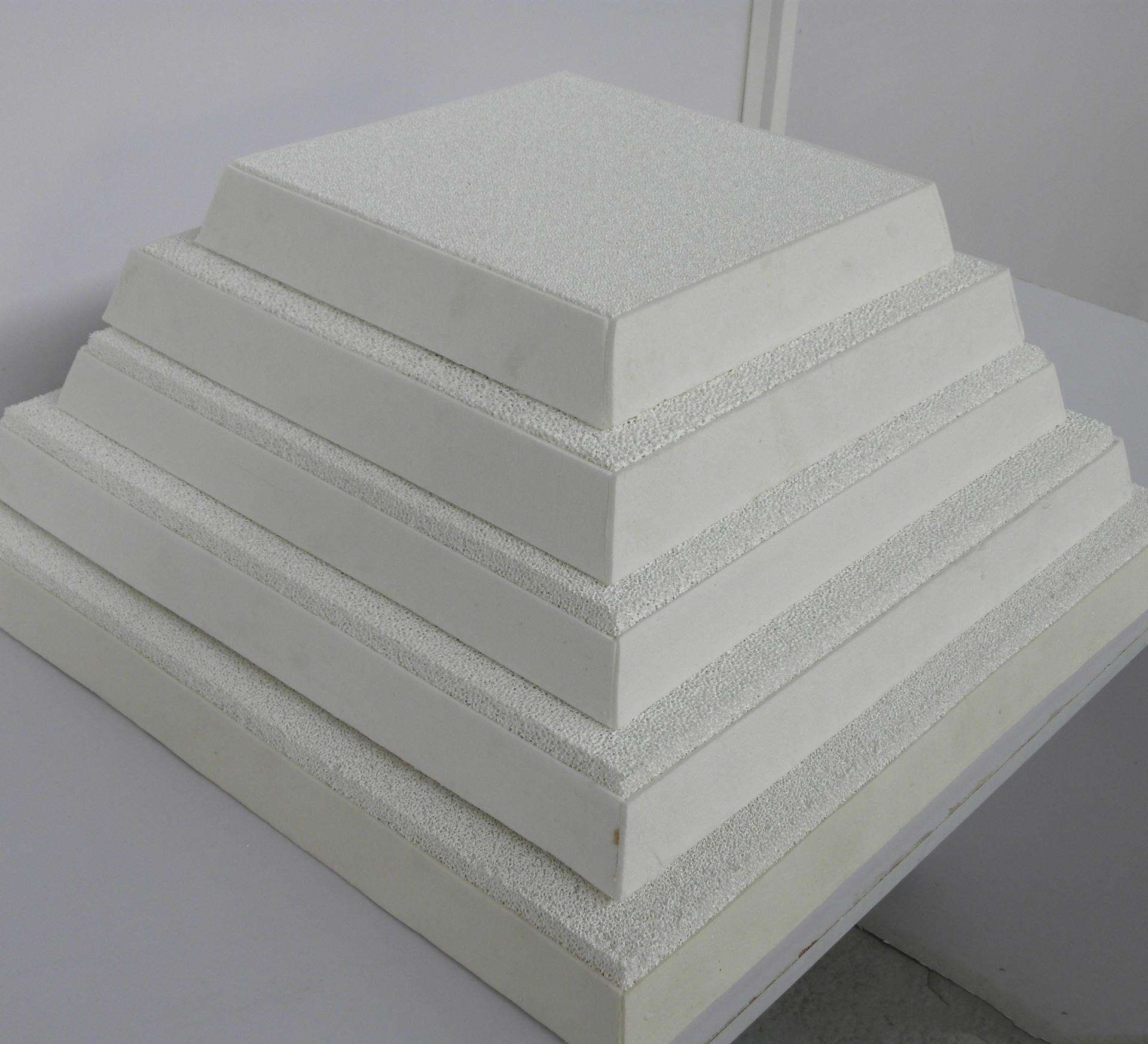

I-Alumina ye-Refractory Porous Ceramic Foam Filter Plate ye-Aluminiyam etyhidiweyo

Imiyalelo yokusetyenziswa kwepleyiti yokucoca ugwebu lweceramic:

Jonga kwaye ucoce inkunkuma kumphezulu webhokisi yokucoca ukugcina ibhokisi yokucoca icocekile kwaye ingenamonakalo.

Beka ipleyiti yokucoca ngobunono kwibhokisi yokucoca, kwaye ucinezele igaskithi yokutywina ujikeleze ipleyiti yokucoca ngesandla ukunqanda ulwelo lwe-aluminiyam ekudluleni okanye ukudada.

Hlaziya ibhokisi yokucoca kunye nepleyiti yokucoca ngokulinganayo ukuze ubenze basondele kubushushu be-aluminiyam enyibilikisiweyo, kwaye iqondo lobushushu langaphambili lecwecwe lokucoca alikho ngaphantsi kwe-260℃.Ukufudumala ukususa amanzi adityanisiweyo kunceda ukuvula ubungakanani bokuqala bokucoca i-pore ngephanyazo, kuthintela ukuvaleka kwepore kwipleyiti yokucoca ngenxa yokwandiswa kobushushu kunye nokucutheka.Ukufudumala kombane okanye igesi kungasetyenziselwa ukufudumeza, kwaye ukufudumeza okuqhelekileyo kuthatha imizuzu eyi-15-30.

Xa uphosa, qwalasela utshintsho kwintloko ye-aluminium ye-hydraulic, kwaye ugcine imfuno eqhelekileyo yokuhamba kwe-aluminium liquid.Intloko yoxinzelelo oluqhelekileyo lokuqala yi-100-150mm.Xa i-aluminium etyhidiweyo iqala ukudlula, intloko yoxinzelelo iya kuhla ngaphantsi kwe-75-100mm, kwaye ke intloko yoxinzelelo iya kwanda ngokuthe ngcembe.

Ngexesha lenkqubo yokucoca eqhelekileyo, kunqande ukunkqonkqoza kunye nokungcangcazela ipleyiti yokucoca.Ngexesha elifanayo, ukuhlamba kufuneka kuzaliswe ngamanzi e-aluminium ukuphepha ukuphazamiseka okukhulu kwe-aluminium liquid.

Emva kokucoca, khupha ipleyiti yokucoca ngexesha kwaye ucoce ibhokisi lokucoca.

| Ubungakanani | Imodeli/ubukhulu (mm) | ppi | Ukupakisha |

| 12 intshi | 305/40 | 20,30,40,50,60 | 10pcs / ibhokisi |

| 12 intshi | 305/50 | 10pcs / ibhokisi | |

| 15 intshi | 381/40 | 6pcs/ibhokisi | |

| 15 intshi | 381/50 | 6pcs/ibhokisi | |

| 17 intshi | 432/50 | 6pcs/ibhokisi | |

| 20 intshi | 508/50 | 5pcs/ibhokisi | |

| 23 intshi | 584/50 | 5pcs/ibhokisi |