I-Aluminiyam ye-Titanium Boron yocingo lwentsimbi yokongeza i-billet casting

Indlela yokuvelisa:

Lungiselela i-ingots ye-aluminium ecocekileyo, i-aluminium enqabileyo yomhlaba i-alloy ingots, i-potassium fluorotitanate, i-potassium fluoroborate kunye nezinye izinto eziluhlaza ngokwezithako zokucoca ezilungiselelwe kwangaphambili;ukushisa kunye nokunyibilika kwee-ingots ze-aluminium kunye ne-aluminiyam enqabileyo yomhlaba kwi-intermediate frequency induction furnace, kwaye emva koko wongeze izinto ezahlukeneyo ezikrwada;I-melt iqala ukusabela kwiqondo lokushisa eliphezulu;emva kokuba ukusabela kugqityiwe, ukugcinwa kobushushu kunye nokususwa kwe-slag kugqitywe, kwaye emva koko kuphonswe kwi-ingot okanye ngokuqhubekayo ukuphoswa kwaye kufakwe kwintonga yocingo.Ngokwemiqathango yenkqubo engentla, i-aluminium ephezulu yokucoca, i-crystals ye-columnar inokupheliswa.Kwimizi-mveliso ye-aluminiyam ecocekileyo kunye nothotho olwahlukeneyo lwealloyi ye-aluminiyam ekhubazekileyo, ubungakanani beenkozo bungacokiswa bube ngaphantsi kwe-100 μm.Inokuncitshiswa ngokuzinzileyo ibe ngaphantsi kwe-2μm;kwi-al-Si alloy, ubungakanani beenkozo bunokucocwa ukuya ngaphantsi kwe-150-200μm.Ngelo xesha, amandla, iplastiki kunye nokuqina kwe-aluminium ecocekileyo ye-industrial kunye ne-alloys ezahlukeneyo ze-aluminium ziphuculwe kakhulu.Intshayelelo yemveliso: Iimpawu: ukulungiswa, kulula ukuyisebenzisa, kwi-aluminium alloy melt.

Sebenzisa indlela:

Yayisetyenziswa ngaphandleeziko, xa amanzi e-aluminiyam ekhutshwa, faka ngokuthe ngqo i-aluminium titanium boron wire kwi ukuhlamba ngeceramicngeumphakeliukunyibilika nokusulungekisa, kunye nokuqinisekisa ukuba ucingo lwe-aluminiyam titanium boron kunye namanzi e-aluminiyam anxibelelana ngaphezu komzuzu omnye (kungcono 2- 10 imizuzu).Umthamo jikelele0.8-1.3kg/toniye-aluminiyam (ububanzi bocingo lwe-aluminiyam-titanium-boron yi9.5mm, kwaye ubunzima bu0.192kg/m).

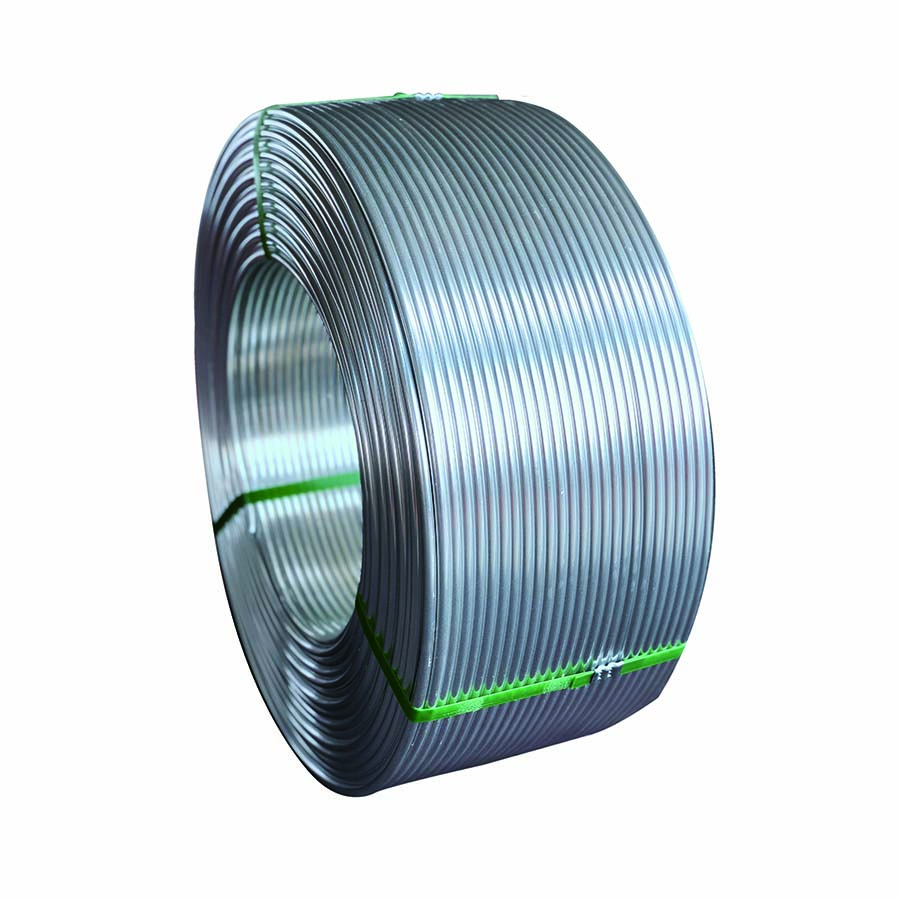

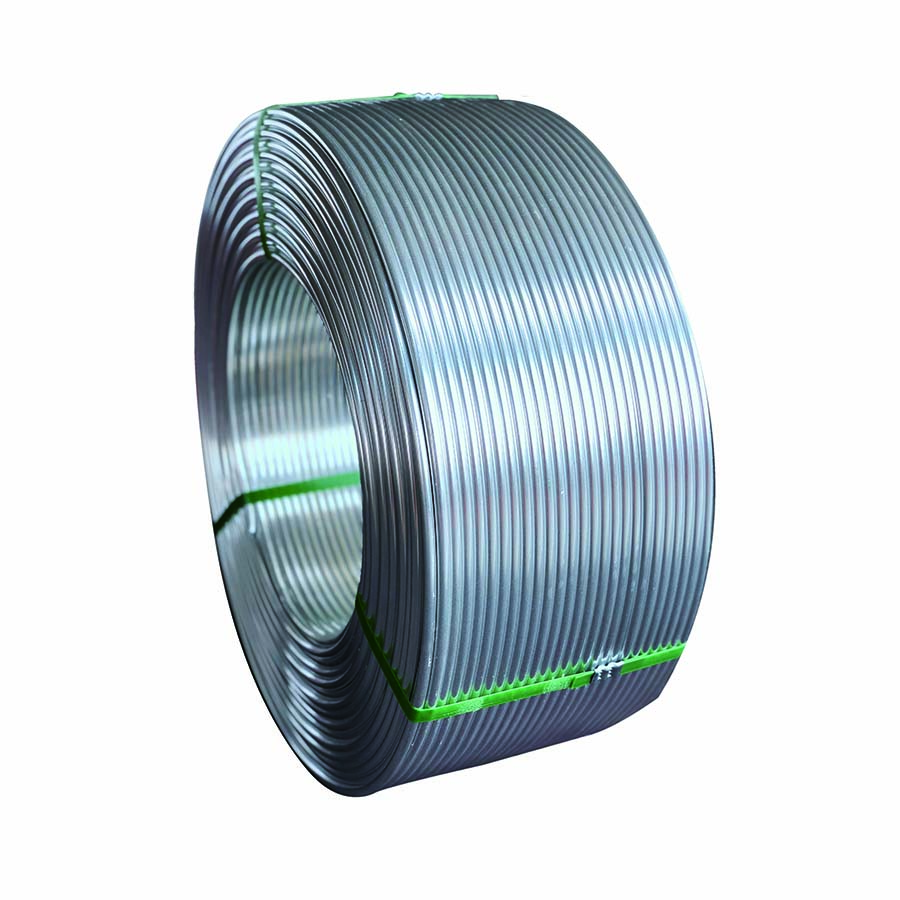

Malunga ne-Φ9.5mm ucingo,umqulu ngamnye umalunga ne-100 kg (170 kg), ukwakheka kocingo lwealloyi yi-5% T 1% B, Umxholo wezithako kunye nokungcola uhlangabezana neemfuno zemigangatho yelizwe GB8736-88.